-

RABS Engineering Works

R - ReliableA - Accurate and attention to details

B - Best methods and systems

S - Supply in time and satisfaction

-

44 year

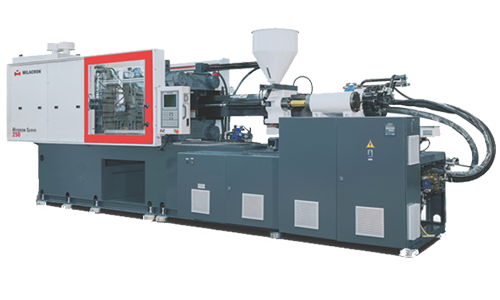

RABS ENGINEERING WORKS, an ISO certified company.

Manufacture items of the highest quality . -

We DO

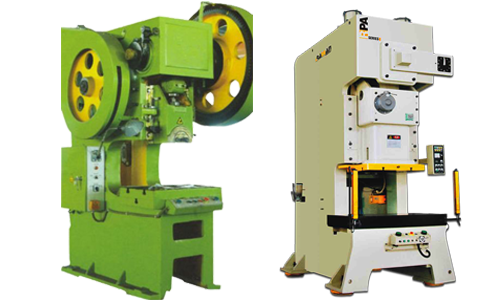

We design and manufacture Plastic Injection Moulds, press tools and manufacture components for

various home appliances, Automotive Industries electrical and electronic industries.